The TOP 5 TYPES OF Polycarbonate roofing Sheets in Bangalore

are divided into 1) Solid Polycarbonate sheets and 2) Multiwall Polycarbonate Sheets.

Again these two TYPES OF polycarbonate roofing sheets’ are subdivided.

Before knowing in detail the TOP 5 TYPES of polycarbonate roofing sheets in Bangalore, it is good to understand in detail, what is polycarbonate roofing sheet, and later understand the top 5 types of polycarbonate roofing sheets in Bangalore available. The top 5 types of polycarbonate roofing sheets in Bangalore are available in different sizes and colors.

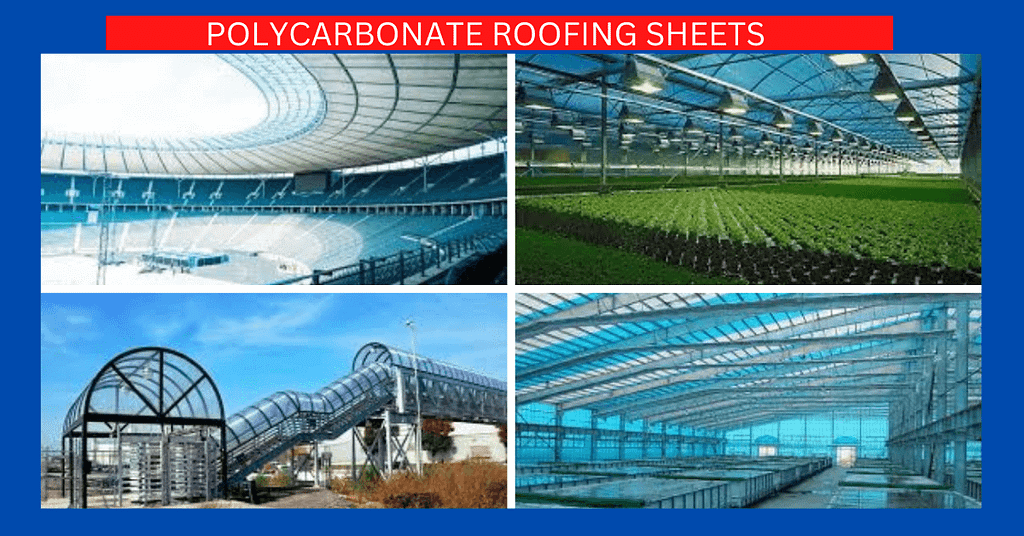

POLYCARBONATE ROOFING SHEETS

Polycarbonate Plastic (PC) sheet is a rigid, amorphous, and transparent thermoplastic that comes in a transparent sheet. A Polycarbonate roofing sheet is the ideal solution for the transmission of natural light (skylight) and roof covering. Architects and construction engineers recommend polycarbonate sheets because they are lightweight and stronger than glass, suitable for all climatic conditions and offer long-lasting services, and are economical.

WHERE ARE POLYCARBONATE ROOFING SHEETS USED?

Polycarbonate is mainly used for electronic applications due to its safety features, being a good electrical insulator, and having heat-resistant and flame-retardant characteristics.

Construction Industry is one of the second largest consumers of polycarbonate sheets. And largely used in residential, industrial, commercial buildings, and public utility places.

Polycarbonate sheets are resistant to heat (provide almost 60% more thermal insulation than glass sheets).

APPLICATION OF POLYCARBONATE ROOFING SHEETS.

• Skylight, lighting for corridors, balconies, passages, and subway entries, walkways, skywalks, pergolas, stadium.carports roofing.

• Conservatories, agricultural greenhouses, zoos, and botanical gardens.

• Industrial wall cladding, roofing, and glazing.

. Privacy glazing, domes, canopies & pyramids.

• Natatorium Swimming pools roofing/ bathroom upholster.

TOP 5 TYPES OF POLYCARBONATE ROOFING SHEETS IN BANGALORE

The top 5 types of polycarbonate Roofing sheets.

- .Solid Polycarbonate Roofing sheets

- Clear polycarbonate sheet.

- Emboss polycarbonate sheet.

- Diamond / Crystal polycarbonate sheet.

- Corrugated polycarbonate sheet.

- .Multiwall polycarbonate Roofing sheets.

Depending upon your requirement, you have a wide choice to choose from multi-wall polycarbonate sheets to compact clear polycarbonate sheets and from embossed sheets to corrugated polycarbonate sheets, each sheet has its own features and usages, color, thickness, and design.

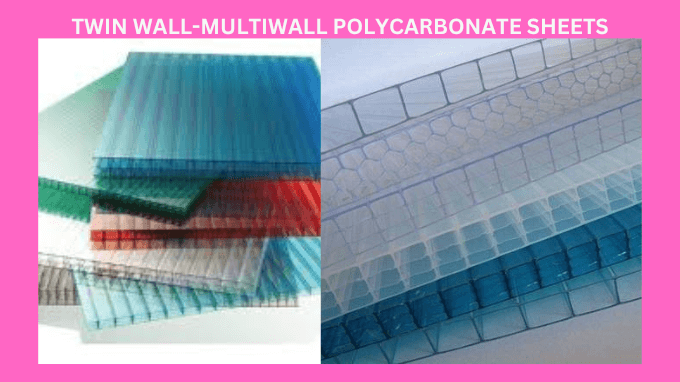

1. Multiwall Polycarbonate Roofing Sheets

Multiwall polycarbonate Sheets are hollow polycarbonate sheets that have two dainty dividers divided by vertical ribs. The standing rib gives significant inflexibility to these sheets, and the sheets are lightweight.

Features of Multiwall polycarbonate Roofing Sheets.

. Provides a maximum of 80% and a minimum of 25% light transmission.

- Temperatures resistance up to 120 degrees Celsius

- Offers UV protection on one side or both sides.

- High level of impact resistance

- Low-rigidity sheets with flexible grades

- Acids and chemical resistant

- Cold deforming

- Low level of flammability

- Excellent weather-resistant

Specification.

Thickness…4mm, 6 mm, and 10 mm. (starts from 4mm)

Width…4’ and 7’

Length per roll…39’.

Colors. Clear / Bronze / Blue / Green / Metallic grey / Opel white

Top seam. Starts from a 12mm (clear) Top seam width.900mm

2. Solid Polycarbonate Roofing sheets.

solid Polycarbonate Roofing sheet is known as safety glass. It is transparent as glass, at less than its weight is dominating the construction industry. It combines superior impact resistance and clarity; it is virtually unbreakable, 30 times the impact resistance of tempered glass, about 200 times of glass, and 20 times of acrylic sheets.

Solid Polycarbonate Roofing Sheets are available in different colors, profiles texture, shades, thickness, and length to choose from and comes with UV resistance features that prevent the transmission of harmful UV rays.

Solid polycarbonate Roofing sheets proved to be the best, as they minimize energy consumption. These long-lasting solid sheets are available at a reasonable price to serve a large section of clients.

Features of Solid Polycarbonate Roofing Sheets

Solid Polycarbonate Roofing sheets provide unbeatable impact resistance.

Provide protection against breakage and shattering.

It is extremely used in safety glazing applications as well as in applications that call for greater crash-resistant protective screening.

Solid polycarbonate sheet is superior to multiwall polycarbonate sheet in light transmission and are impact resistant.

Specifications.

1) Color: Clear/ Opel white / Bronze.

2) Thickness: 1 mm.

Width. 4’ Length. 110’

3) Thickness: 1.5mm, 1.8mm, 2mm & 3mm.

Width: 4’ &7’ Length. 110’

4) Thickness: 4mm

Width: 4’& 7’ Length. 50’

5) Thickness: 5mm, 6mm, 8mm, 10mm.

Width: 4’ Length: 8’

6) Single-sided and both-sided UV protection.

3. Embossed polycarbonate Roofing sheets.

An embossed polycarbonate Roofing sheet is an extension of a solid polycarbonate Roofing sheet. Embossed polycarbonate Roofing sheets are mainly used as decorative materials for their unique surface, lightweight, and unbreakable quality.

its acceptance is due to the fact that they can be used in partitions to protect privacy with their translucent surface, are installed easily, are stable under harsh environmental conditions, and offer high tensile strength.

Apart from light transmission (40% to 72%), polycarbonate embossed sheets also have capabilities of high impact strength, UV resistance, flame retardant, and High-temperature resistance.

The particle surface spreads the sunlight and decreases light pollution. Particles can be created into different shapes and sizes to achieve the required blur effect. Regular shapes of particles are similar to diamonds, water-drop, and heart-shaped.

Specification.

Thickness- 1.5mm, 1.8mm, 2mm, and 3mm.

Length: up to 110’ (Depends upon Brands. 50’ 100’ and 110’)

Width: 4’ &7’

Colors- green /blue/ grey /solar bronze/ clear/ Opel white.

4. Corrugated Polycarbonate Roofing Sheets.

corrugated Polycarbonate Roofing sheets are highly beneficial in increasing daylight and possess fire-resistant properties and have maximum strength and durability to withstand high wind, hail, and heavy snow damage.

The required profiles are manufactured with precise specifications to find an appropriate use in industrial, commercial, residential, and warehouses for skylights and are available in clear only.

Specification:

- Thickness: 2mm in several profiles ( zinc sheets & GI sheets)

- Length: Up to 23’

- Width. 3.5’

- Custom sizes are available for special order

- Colors: Clear/ Bronze / Opel White.

- Available in both Clear & Emboss.

Comparison between FRP & Polycarbonate Sheet

Most of the time the end consumer feels that FRP (Fibre reinforced Plastic) and polycarbonate sheets are one and the same and are usable for roofing but both are different.

Polycarbonate sheets are cost-effective skylight roofing materials and are popular among builders and designers. It has UV protection layers that prevent discoloration, despite its daily exposure to sunlight and UV rays.

FRP (Fibre Glass) on the other hand is majorly used for roofing and partitions and is made of glass fibers.

Polycarbonate sheets can withstand high-impact pressure and are four times stronger than Fiberglass of the same thickness.

Polycarbonate sheets have no fibers that allow them to maintain color, shape, and strength even when exposed to UV rays. Fiberglass cannot withstand extreme heat, and exposure to heat causes the fibers to deteriorate which causes discoloration and yellowing.

A comparison between FRP and polycarbonate sheets is mentioned below:

| Property | Polycarbonate | FRP |

| Impact | Excellent | Good |

| Weather | Excellent | Good |

| Temperature Resistance | Up to 120 Deg. C | Up to 100 Deg. C |

| Light Transmission | UP to 89% | 80.00% |

| Fire Sprayed | Self-Extinguishing | Flammable |

| Thickness | Uniform | Varying |

| Maintenance | Easy | Difficult |

| TAC Approval (% of Total Roof Area) | 5.00% | Only 2% |

Difference between polycarbonate and acrylic sheets?

Both are different materials most of the time they are compared because they are similar in appearance and see-through plastic materials.

Generally speaking, acrylic sheet is shinier and polycarbonate sheet is tough

Acrylic and polycarbonate both are much stronger than glass. Both materials are easy to clean.

One of the major differences between acrylic and polycarbonate is the cost. Polycarbonate sheets cost35% more than acrylic.

Polycarbonate and acrylic sheets, share some similarities in types of sheets like clear, color, mirrored, and more. While the shape and appearance may be the same, you will find that a clear polycarbonate sheet and a clear acrylic sheet are largely different due to the physical and chemical properties of the plastic.

Selecting one over the other depends entirely on the specific needs of your application.

If you are looking for clarity and light, acrylic sheets will beat polycarbonate sheets. On the other hand, if you are looking for high-impact resistance, polycarbonate sheeting is the best choice. Acrylic sheets are the best choice for Glow sign boards.

Difference between twin-wall and multiwall polycarbonate?

Twin-wall and multi-wall are of the same property, but the major difference is that the twin wall is double-layered, while the multi-wall has more layers.

More the thickness of the polycarbonate panel, the more insulation it provides. But lesser light transmission. Inconsistency in light transmission may arise for bronze/opal layered materials. For bronze coated, the light transmission will be 33% and 40% for opal. It also helps to create a roof over the plants that require the least sunlight.

Otherwise, a solid polycarbonate sheet with a UV coating can also be used as a roofing panel, with a lifespan of more than 10 years.

The twin-wall polycarbonate sheet comes in three categories.

4mm Polycarbonate Sheet

Polycarbonate sheets with UV ray protection are used for greenhouse glazing. This allows 85% light transmission, and the heat insulation is minimum and gives a mini curve radius of 600mm.

6mm Polycarbonate Sheet

It is unbreakable, durable and gives better thermal insulation than glass due to its twin-wall property, and allows 82% of light transfer.

10mm Polycarbonate Sheet

Best suitable for greenhouses as it provides the best thermal insulation compared to other twin-wall materials. It allows 80% of light transmission.

Why Do You Require Multiwall Polycarbonate?

Multiwall polycarbonate has been used as an alternative to glass for carports, greenhouses, skylights, patio covers, etc. It comes in various sizes.

16mm Multiwall Sheet

These polycarbonate sheets are used for carports and greenhouses as they provide excellent thermal insulation, but the light transmission is less than the twin wall.

25mm Multiwall Sheet

These sheets are used for patio covers, pergolas, and garden roofs for plants that require less sunlight as they allow 62% light transmission, but have exceptions for bronze (11%) and opal (28%).

You might use a dark-coated multi-wall to reduce light transmission for your plants. Before using you need to know how much light your plants are required.

35mm Multiwall Sheet

35mm multiwall can be used for the construction of a conservatory. It’s lighter than glass.

The light transmission is 63%, which means you can rest under this roofing and protect yourself from direct sunlight. These are not applicable to greenhouses generally. The nominal sheet weight is 3.9kg/m2.

If you want to do something new to attract the attention of the tourists, you might set up a close area conservatory on hilly areas or sea sides for visitors/tourists to have great fun fare, and entertainment to enjoy this unique feature.

These are polycarbonate facade panels, the normal colors are clear, opal white.

POLYCARBONATE ROOFING SHEETS-ACCESSORIES.

- C-Cap for Multiwall for 6mm and 10mm

- L-angel for 4mm

- Aluminium Roofing Top.& Bottom

- EPDM Rubber

- Weather Proof sealant.

Polycarbonate Roofing sheets Brands.

1. Lexan

3. Palram

4. Polyglaze

Other than the above brands there are regional brands.

Frequently Asked Questions:

I) Is polycarbonate sheet good for roofing?

Polycarbonate sheets are very strong, that has an impact resistance of 200 times that of glass. This amazing property makes the polycarbonate roofing system highly durable and long-lasting because there is no worry about cracking or breakage.

2) Which is more expensive acrylic or polycarbonate?

Polycarbonate sheets cost 35% more than acrylic.

3) Which is cheaper glass or polycarbonate?

Polycarbonate is less expensive than glass.

4) How Long Does Polycarbonate Roofing Last?

Polycarbonate roofing panels can last anywhere between 10 and 20 years if maintained properly.

5) Can you walk on polycarbonate roofing sheets?

Polycarbonate roof sheets are not designed to support the weight of a person and one should avoid walking on them. If you need to access the roof sheets, use crawl boards between the rafters or step ladders as a safe means of doing so.

Conclusion:

We have discussed polycarbonate sheets, different types, sizes and applications, and benefits.

About the Author:

Fayaz Uddin, Founder- Roofing Insights

Web Designer, Digital Marketer, Content writer, and Guest Blogger at IIM SKILLS.

Sales & Marketing Professional with 25+ years of experience in different fields.